FOSTER, from sludge tot energy- and materials recycling

From 2026, new installation will recover energy and raw materials from the waste water of 4 million Flemish citizens

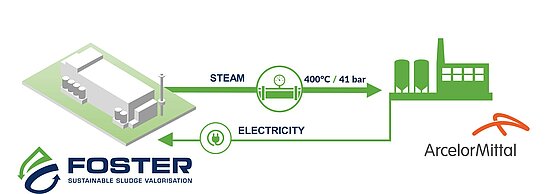

Water treatment company Aquafin is to build a sewage sludge processing installation on the ArcelorMittal site in the port of Ghent, to be operational by 2026. Both companies will apply the green energy produced there to further reduce their CO2 impact. Aquafin is also planning the large-scale recovery of phosphorus, used among other things in fertiliser. The contract for the design, construction and financing of the installation and its maintenance until 2046 has been awarded to the BESIX/Indaver consortium.

Maximum recovery of energy and materials

The installation is intended to process the biomass that remains after the purification of domestic waste water. This biomass, created by the growth of the micro-organisms that do the purifying work, contains a wealth of energy and raw materials. Aquafin already produces fully green energy on this basis, in the form of biogas, and right now at one Antwerp location also biomethane, for injection into the natural gas network. The new installation, which should be operational in 2026, will be able to make even more use of the biomass delivered to it. As this is a mono-processor, the sludge will not be diluted with other substances, enabling maximum recovery of energy and raw materials.

Sludge as valuable source of energy and materials

The sludge mono-processor will carry out the end treatment of two-thirds of all Flemish sludge from domestic waste water. In a follow-up phase, Aquafin is planning to start up full-scale phosphorus recovery, representing some 2,000 tonnes of pure phosporus a year. By opting for mono-processing, phosphorus can be recovered more efficiently from biomass.

Partnership

Using a European tender procedure with competition-oriented dialogue, Aquafin went in search of a partner for the design, construction, financing and maintenance of the mono-processor. The DBFMO contract was awarded to the BESIX-Indaver consortium, which set up the Special Purpose Vehicle 'FOSTER' for this purpose.

Indaver and BESIX are two respected international and value-driven industrial partners on the Belgian market. Each in its field, they have already successfully completed many large industrial projects, both in Belgium and abroad. Both companies create added value for the customer and for society by putting care for people, safety and the environment first. To make a success of this sludge mono-processor project, they are purposefully combining their largely complementary knowledge and experience.

Visit the FOSTER website (Dutch)